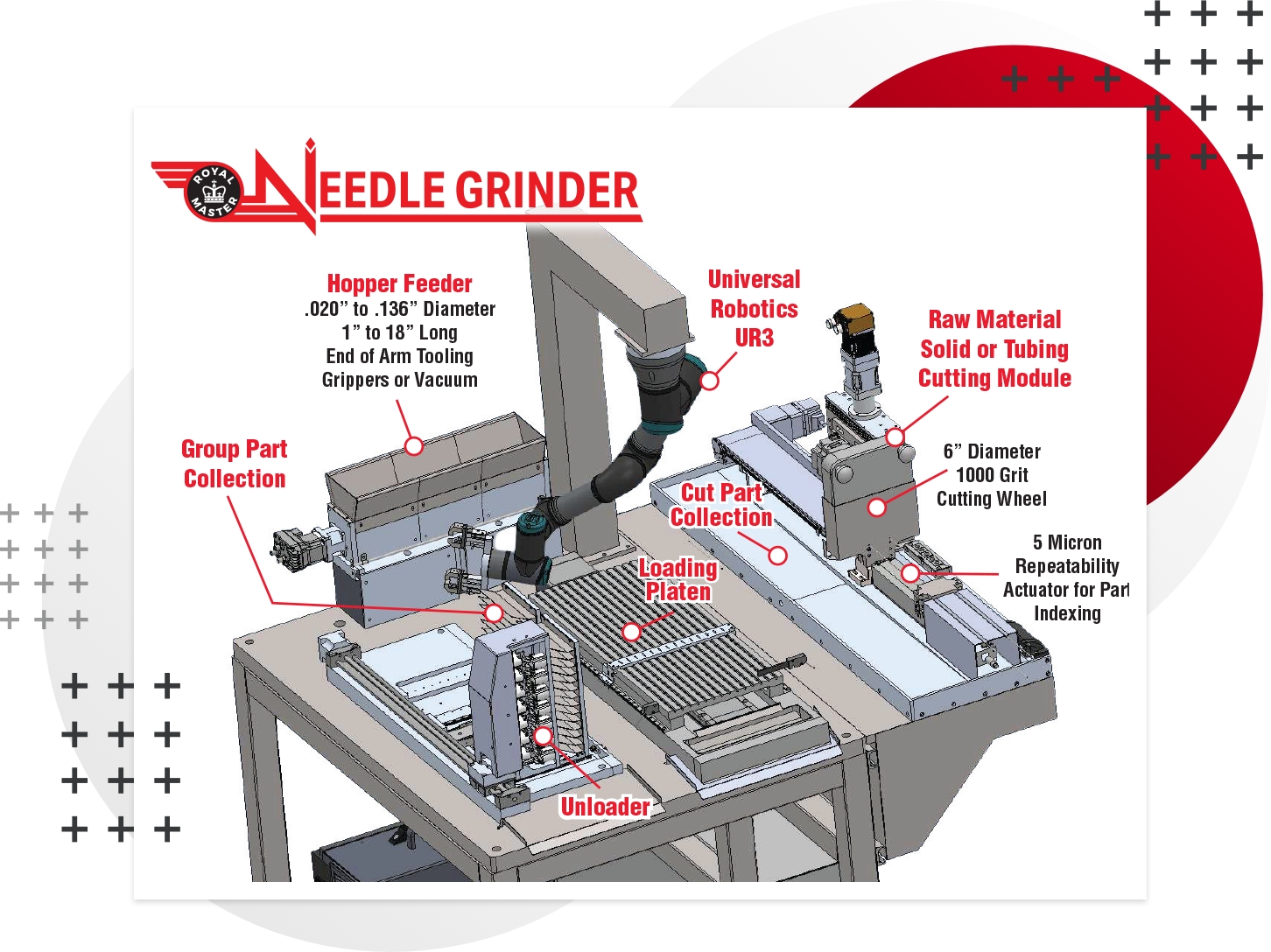

Automation

Utilizing the Needle Grinder system eliminates the need for expensive tooling or multiple cartridges. Users can easily load cut needles into the hopper and initiate the process with the cycle start button, streamlining the operation. Additionally, the system can accommodate spool-fed solid needles made of materials like NiTi or SLT from various suppliers.

Fully Automated Process

- The process involves the Universal Collaborative UR3 robot.

- It loads two needles at a time from the drum hopper and places them into a platen

- Once filled, the loading mechanism pushes the parts into the end effector.

- Spring plungers in each pusher accommodate differences in part lengths.

- The grinding process begins as the parts enter the end effector.

- Upon grinding completion, the end effector moves to the unload station.

- 14 grippers within the end effector grab the needles, ensuring separation and placing them into individual trays.

- Custom loading and unloading solutions are also available

Semi-Automated Solution

- This option omits the robot and unloader, suitable for operator-paced operations.

- The semi-auto system consists of the loader platen.

- Operators load the platen and manually unload the needles.

- An optional unloader module can be added if desired.

Manual Solution

- This option allows for entirely manual loading and unloading of the end effector.

- A video demonstration offers a visual overview of the loading, grinding, and unloading procedures, showcasing available machine functionalities and options.