Automation

The goal of the Needle Grinder machine by Royal Master was to achieve full automation, eliminating the need for customer interaction with the grinder.

This automation extends to the loading and unloading of the end of arm tooling, eliminating the need for operators to handle cartridges.

By utilizing the Needle Grinder system, there is no requirement for multiple cartridges or expensive stainless steel tooling to improve efficiency. Instead, users can simply place cut needles into the hopper and press the cycle start button, making the process incredibly straightforward. Additionally, the system has the capability to spool feed solid needles of materials such as NiTi or SLT from Fort Wayne or other suppliers.

Fully Automated Process

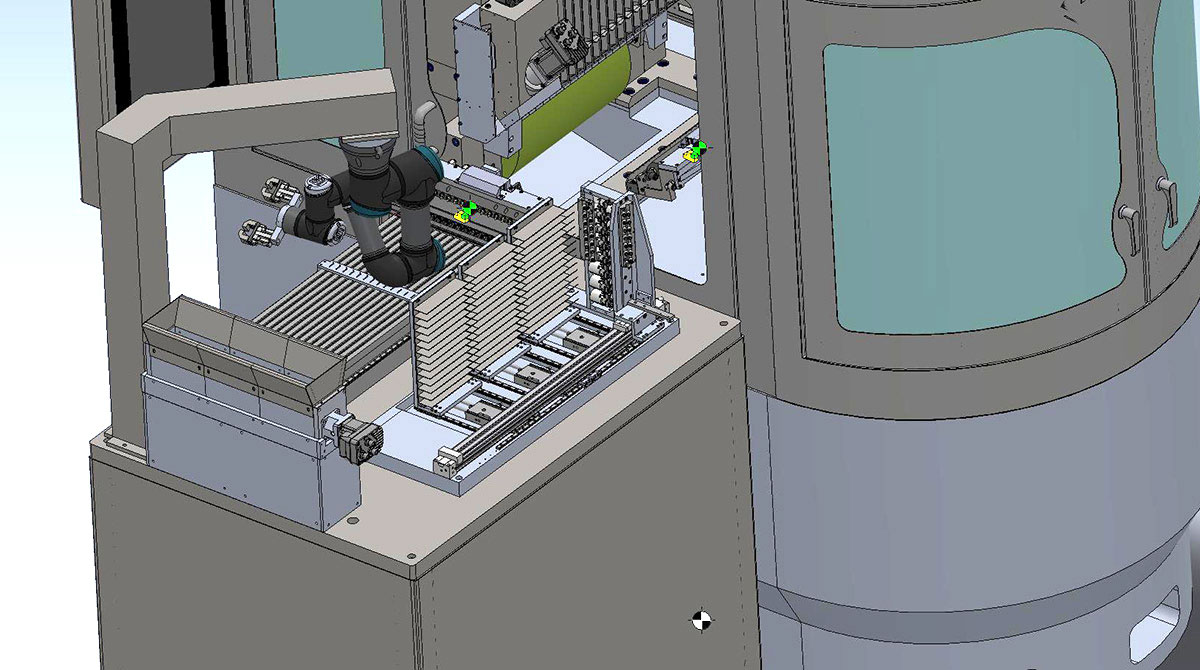

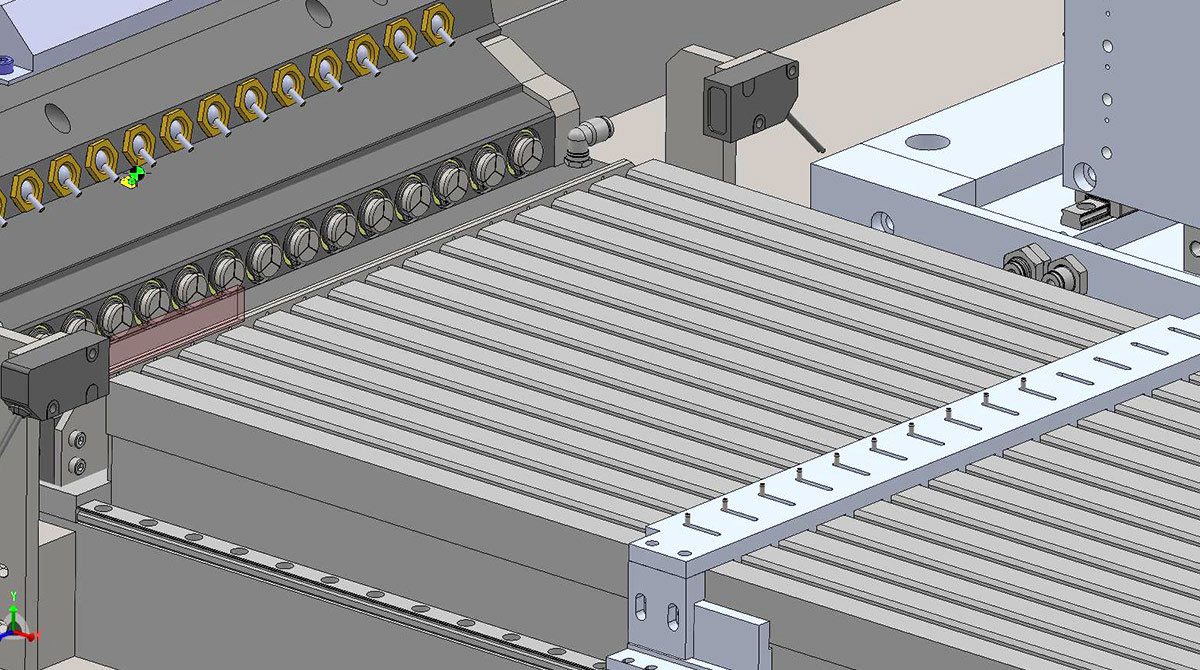

The fully automated process of the Needle Grinder machine involves the Universal Collaborative UR3 robot, which loads two needles at a time from the drum hopper and places them into a platen. Once filled and the end of arm tooling is emptied by the unloader, the loading mechanism efficiently pushes the parts into the end effector. The system incorporates spring plungers in each pusher to accommodate differences in part lengths. As the parts are pushed into the end effector, the grinding process begins.

Upon completion of the grind, the end effector moves to the unload station. The 14 grippers within the end effector grab the needles, pulling them from the collets and placing each needle into its own tray, ensuring separation of the end effector collets. The part receptacles also serve as convenient carrying trays.

Semi-Automated Solution

If full automation is not necessary and you prefer a semi-automatic solution with operator pacing, the semi-auto system offers a suitable option. The semi-auto system consists of the loader platen without the robot and unloader. In this setup, the operator is responsible for loading the platen and manually unloading the needles. However, if desired, the unloader module can be added.

Manual Solution

Alternatively, manual loading and unloading of the end effector is also available as an option. View the video below to gain visual insight into the loading, grinding, and unloading procedures, providing a clear overview of the machine’s functionality and available options.